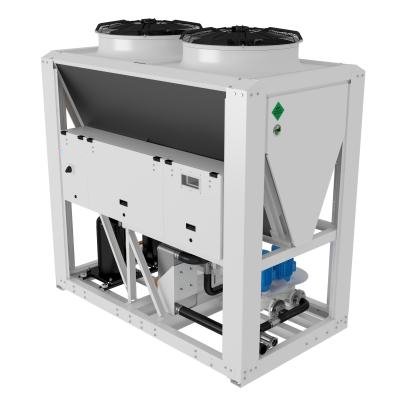

CSCM CU

Description:

Condensing units 55,0-173,7 kW. Efficient, reliable and low-noise nordAQUA CSCM CU product line. The range is made featuring scroll compressors and R410A refrigerant. Small footprint, high energy efficiency and wide range of options are key features of CSCM CU condensing units. Integrated hydronic module is available as an option. 11 capacity sizes. For standard application.

Versions:

(1) CSCM CU standard version;

(2) CSCM CU LN low noise;

(3) CSCM CU HE high efficiency.

Key options:

(1) Condensing pressure regulation with variable fan speed or condenser bypass for low temperature and low noise operations;

(2) Protective grills;

(3) Coating for coils;

(4) Integrated hydraulic module;

(5) Partial or total heat recovery.

Accessories

|

131A 131C 131D 132D 132A 132B 132C 133A 231 232A 232B 234 235 431A 431B 432B 432C 434A 437 531A 531B |

Anticorrosion coating e-coating for the capacitor Antikorrozinoe cover BlyGold capacitor Condenser, abutment-chivy to aggressive environment Decorative and protective panels Protective grille for the condenser Windshield capacitor Safety net for the capacitor Fan with EC motor Silencer hoods for compressors Sound insulation boxes for compressors Low-noise fans Maffler Discharge Antivibration hose on the discharge line Thyristor speed W speed control Electric heating hydronic Heater control cabinet Hot gas bypass The system of regulation of the condensing pressure Soft start compressors Phase monitor |

531C 532 533 534 535 536 537A 537B 631A 631B 632A 632B 633A 634A 635 731A 732A 831A 832A 833 834 |

Power factor correction Circuit Breakers Manometers of high and low pressure External display control RS-485 interface Gateway PCO WEB Indicator lights compressor is on Indicator lights turned on the heater Antivibration mounts (rubber) Anti-vibration mounts (spring) Joining Victaulic Flange connections Painting unit in the color selected by the customer Providing at + 48 ° - keeping the refrigerant condensers Installation Partial heat recovery A full refund heat Ball valve on the suction line Ball valve in the discharge line Pressure relief valve on the discharge line The solenoid valve of the liquid line |

TECHNICAL CHARACTERISTICS:

|

CSCM CU |

055.2 |

060.2 |

070.2 |

085.2 |

090.2 |

110.2 |

125.2 |

135.2 |

145.2 |

160.3 |

170.2 |

|

Cooling Capacity, kW |

55,0 |

63,6 |

70,9 |

80,6 |

91,5 |

111,4 |

122,9 |

134,1 |

149,0 |

167,4 |

173,7 |

|

Total Power Input, kW |

19,6 |

20,1 |

23,4 |

28,4 |

32,8 |

35,1 |

40,5 |

45,9 |

52,6 |

52,5 |

56,9 |

|

EER |

2,81 |

3,16 |

3,03 |

2,84 |

2,79 |

3,17 |

3,03 |

2,92 |

2,83 |

3,19 |

3,05 |

|

ESEER |

3,67 |

4,01 |

4,04 |

3,93 |

3,96 |

3,99 |

3,93 |

3,86 |

3,85 |

4,12 |

3,96 |

|

No of compressors / circuits |

2 // 1 |

2 // 1 |

2 // 1 |

2 // 1 |

2 // 1 |

2 // 1 |

2 // 1 |

2 // 1 |

2 // 1 |

3 // 2 |

2 // 1 |

|

Sound power, dB(A) |

78 |

78 |

79 |

80 |

83 |

85 |

87 |

88 |

88 |

87 |

88 |

|

Sound pressure at 10 m, dB(A) |

50 |

50 |

51 |

52 |

55 |

57 |

59 |

60 |

60 |

59 |

60 |

|

Length, mm |

1223 |

1223 |

1223 |

1223 |

1223 |

1223 |

1223 |

1223 |

1223 |

2443 |

2443 |

|

Width, mm |

1619 |

1619 |

1619 |

1619 |

2222 |

2222 |

2222 |

2222 |

2222 |

2222 |

2222 |

|

Height, mm |

2305 |

2305 |

2305 |

2305 |

2305 |

2305 |

2305 |

2305 |

2305 |

2305 |

2305 |

|

Operating weight, kg |

487 |

523 |

531 |

533 |

699 |

833 |

856 |

878 |

893 |

1278 |

1208 |